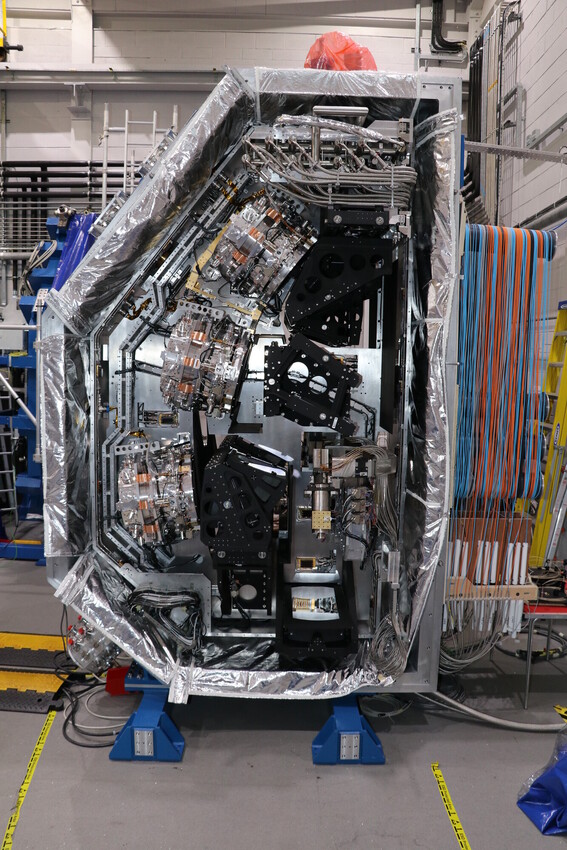

Because MOONS operates in the infrared it needs to be extremely cold to function, otherwise the heat from the instrument itself would overwhelm its own sensors. The components give off less noise, light and heat, when you cool them right down.

Logistically it's impossible to build a complex science instrument like MOONS at the temperature it operates at. Especially when you consider that the optical bench must be cooled down to 130 Kelvin (approximately -140 Celsius) and the detectors to 40 Kelvin (-230 Celsius).

Therefore, you need a warm to cold translation drawing for MOONS. This converts the optical element positions from the mechanical model (where these optical elements will be at room temperature) to the optical model (based on MOONS operating temperature, ie incredibly cold). This translation drawing must take into account the fact that materials shrink at different rates as they cool.

This isn't a phenomenon that only affects MOONS. Numerous astronomical instruments work well below freezing (including MIRI on JWST). There are charts and guides that tell you the amount and rate materials contract, many of these were developed by NASA when they were working on the Shuttle and are still used today.

Shrinkage is more consistent if you use the same materials, so on MOONS we use the same grade of aluminium for as many components as possible. The advantage being that these parts can be precisely machined at room temperature and will maintain their relative precision to each other when cold.

Most of MOONS is 6082 aluminium. This shrinks in proportion to its length when cooled. Aluminium shrinks by around 0.325% at MOONS operating temperature (130K/-140C).

This may not sound like much, but it means something 1 metre long at room temperature has shrunk 3.25mm at operating temperature. MOONS optical bench is 3.2 metres across its longest dimension, so shrinks by over 10mm.

This may not sound like much, but it means something 1 metre long at room temperature has shrunk 3.25mm at operating temperature. MOONS optical bench is 3.2 metres across its longest dimension, so shrinks by over 10mm.

Of course, it isn't possible to use the same material for everything, so you need to calculate how different materials contract at different rates. There are six cameras in MOONS, their lenses are glass and the support structure is aluminium. If you get your maths wrong the surrounding metal ring will shrink and the glass could shatter.

The cameras must stay concentric, so they are one of the most complicated aspects of MOONS. Glass doesn't really shrink but it is annoyingly fragile at all temperatures. We built in springs all the way around because you don't want the glass to come into direct contact with the metal.

The springs have Teflon tips at the end that press against the glass. Teflon is nice as it is still a little soft when cold, but on the downside it shrinks a lot.

The springs have another advantage, as MOONS also needs to survive shipping (in this case from Edinburgh to Chile) so everything needs to be held securely in place at all temperatures.

The mechanisms in MOONS are another factor we need to consider. As they need to align more precisely than the other parts to work. So often the gears are a bit loose when they're warm. They don't mesh properly until they're cold.

Gears need lubricating but standard lubricants don't work at these incredibly cold temperatures. They go hard. You must use solid lubricants instead, which is an interesting science all by itself.

Bearings are also complicated. If you put a stainless-steel bearing in an aluminium housing, when you cool it down, the aluminium shrinks onto the bearing and basically locks it up. So, we have to design solutions to stop that happening.

Adding all these elements adds another whole layer to the design and mechanical process. And you are trained to look for problems, it is no surprise that Murphy was an engineer, and unfortunately his law 'anything that can go wrong will go wrong' is still applicable today. To ensure things don't go wrong you have to think of nearly every possible failure. It's definitely an interesting challenge.